|

| Production Facilities |

|

| Production process in Mustafa & Mujtaba Textiles starts after receiving of fabrics and end after dispatching of packed garments. Generally export house put quality check points at the end of each process to ensure that only quality pieces move to the next process. Department wise quality check points have been explained in the following |

|

| Weaving |

Machines are equipped with latest technology and the equipments |

| Fabric Store |

100% fabric inspection |

| Cutting |

|

| Marker checking |

| Cut parts checking or audit |

| Bundle inspection |

|

|

| Printing and Embroidery |

|

| 100 % inspection of printing panels |

| 100% inspection of embroidery |

|

|

| Sewing Department |

|

| Inline check point (at critical operation) |

| Roaming checking (Random checking) |

| End of Line checking (100%) |

| Audit of checked pieces |

|

|

| Finishing Department |

|

| Initial finishing inspection (after wash) |

| Final finishing inspection (After Pressing) |

| Internal shipment audit |

|

|

|

| Weaving |

|

|

|

Mustafa & Mujtaba Textiles have a team of supervisors who are always visiting these looms to ensure quality knotting and timely delivery of orders. For the production of, bed Linen, House Hold & accessories.

The Company Sources yarn indigenously from world-class spinning mills of Pakistan. The Stringent level of inward inspection system ensures that the highest level of yarn quality standard are maintained. The Company has the Production facility based on "PROJECTILES-SULZER" & "RAPIER-AIRJET" Technology. |

|

|

| Fabric Store |

|

|

|

In the fabric store fabric is being checked before issuing it to cutting department. In general not all the fabric is checked. Usually 10% of fabrics are checked for good fabric suppliers. For power loom fabric and printed fabric 100% checking is done. Fabrics are checked in flat table, flat table with light box or on fabric checking machine. 4 point system for fabric inspection is used to measure the quality level of the incoming fabric. |

|

|

| Cutting |

|

|

|

Mustafa & Mujtaba Textiles have centralized cutting department working under the supervision of skilled unit manager. The measurement is checked by concerned Export Executive and QA Inspector prior to bulk production. We have the extensive facilities that ensure the skill levels in production. Our cutting department is equipped with Gerber computerized cutting machines. We also cut with hand cutting machines for sample or custom orders. customer specifications. We have the capability to cut a variety of fabrics including knits, wovens, outerwear, fleece, and bedding fabrics. |

|

|

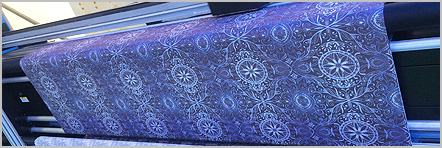

| Printing and Embroidery |

|

|

|

Our Printing Department, equipped with most modern Printing Machines, the latest of which is installed in few year ago. We are capable of printing 21 colours on fabric up to a width of 3200 mm, and repeat sizes ranging from 641 mm to 1200 mm is the best available. Embroidery facility

allows us to rapidly translate designs onto

fabric guaranteeing prompt and reliable

service to our Customers. |

|

|

| Sewing Department |

|

|

|

New and novel sewing techniques that comply the cherishes by translating the dreams of the customers. Before bulk sewing the QA inspector confirm the specifications as stated on stitching orders/quality manual. Each and every piece is checked on table by our trained table checkers only fault free pieces move to the next stage. We maintain record of table checking for each & every piece. |

|

|

| Finishing Department |

|

|

|

Checking done prior to pressing of the garment at finishing room is known as initial finishing. After pressing garments are again checked and passed for tagging and packing.

If the completed work is being checked at each process and defective pieces are corrected before handing to the next process than at the end of production there is very little chance to have a defective at final inspection stage. |

|

|

|

|